Capabilities

Lexatys develops unique, compact designs that optimize performance while minimizing package size. Our capabilities include miniaturized lumped element filtering, laser-tunable surface mount filters, integrated assembly design up to 40 GHz, and high power, hermetic filter packages. Lexatys has designed and built several integrated assemblies that operate from below 6 GHz up to 50 GHz in range.

Partial description of Lexatys’ manufacturing support capabilities:

• Dedicated In-House laser micromachining capabilities that allow fine tuning of miniature filters as well as custom trimming of PCBs for optimum RF performance

• In-house environmental testing for live RF measurements or automated temperature cycling

• Laser machining of custom gaskets, substrate materials, and absorber materials that allows rapid addition of performance enhancing features to improve isolation

Partial list of in-house equipment:

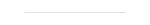

• Keysight N52X PNA 2 and 4 port Network Analyzers to 50 GHz

• Agilent E4440A 26.5 GHz PSA Spectrum Analyzer

• Agilent E8257D 40 GHz Signal Generator

• Anritsu 37369A VNA 2 Port 40 GHz Network Analyzer

• Keysight 8753 VNA 2 Port 6 GHz Network Analyzer

• Modeling Capabilities in Genesys with Momentum, Solidworks Pro, Sonnet EM Pro, Altium PCB Designer

• Class 10,000 clean room with semi-automatic wire bonding and die attach capabilities to ensure first pass success and rapid prototyping

• Dedicated In-House laser micromachining capabilities that allow fine tuning of miniature filters as well as custom trimming of PCBs for optimum RF performance

• In-house environmental testing for live RF measurements or automated temperature cycling

• Laser machining of custom gaskets, substrate materials, and absorber materials that allows rapid addition of performance enhancing features to improve isolation

Partial list of in-house equipment:

• Keysight N52X PNA 2 and 4 port Network Analyzers to 50 GHz

• Agilent E4440A 26.5 GHz PSA Spectrum Analyzer

• Agilent E8257D 40 GHz Signal Generator

• Anritsu 37369A VNA 2 Port 40 GHz Network Analyzer

• Keysight 8753 VNA 2 Port 6 GHz Network Analyzer

• Modeling Capabilities in Genesys with Momentum, Solidworks Pro, Sonnet EM Pro, Altium PCB Designer

• Class 10,000 clean room with semi-automatic wire bonding and die attach capabilities to ensure first pass success and rapid prototyping

|

Laser Tuning

An early innovation to emerge from Lexatys engineering was the ability to custom machine and trim microwave circuits using purpose built 535 nm CNC lasers. The cycle time from initial design to functioning prototype is measured in hours instead of weeks that is usually expected from other vendors processing high permittivity dielectrics. Lexatys works with microwave laminates, alumina ceramic, and various titanate materials to manufacture extremely compact RF filters, couplers, and switching circuits. Lexatys’ engineers are constantly evaluating new dielectric materials to optimize performance. |

|

Testing Capabilities

With extensive use of X-Microwave’s 70 GHz RF probing system, Lexatys technicians align, verify, and record data for critical sub-assemblies prior to integration. As early adopters and developers of hardware using this broadband interface technique, the company has developed an extensive line of custom fixtures, components, and processes that enable rapid prototyping as well as statistical analysis of critical processes. |

|

Wire Bonding

Our West Bond Model 454647E Semi-Automatic Wire Bonding systems include targeting camera and monitor, microscope, heated stage, illuminator, bond heads for ball bonding, and wedge bonding. The programmable, precisely-controlled bond lengths allow Lexatys engineering to precisely regulate the impedance of RF connections. When wire bonds form elements of microwave filters, these controlled inductance values are integral circuit elements. |

|

Volume Manufacturing to 50GHz

Lexatys has significantly invested in modern microwave test equipment and now maintains measurement capability up to 50 GHz. Our commitment to manufacturing excellence includes development of automated measurement systems as well as mechanically automated (robotic) part handling. We have produced 27 GHz microwave block downconverters (BDCs) at a rate of one per day for extended periods. These production cycles include 100% testing with detailed performance data and quality reports. |

|

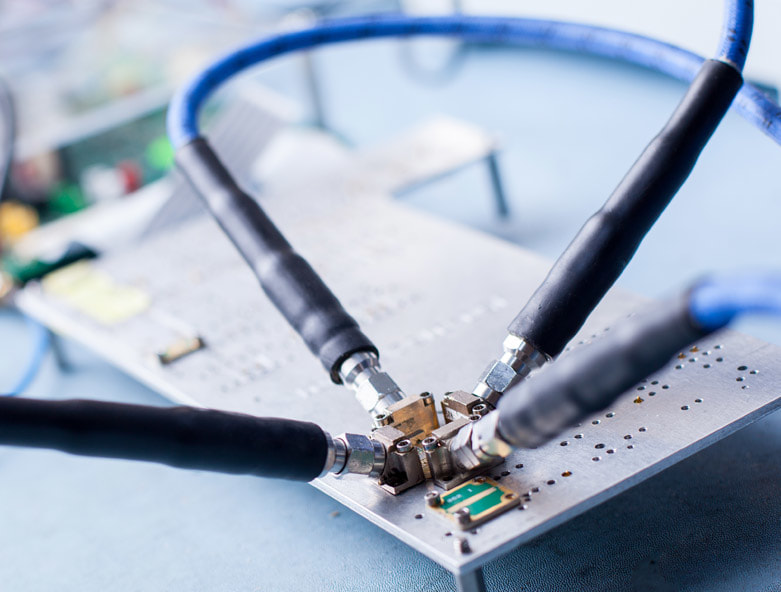

CAD Design

Our design staff puts decades of experience in the design-to-order microwave arena to effective use addressing the challenges posed by a customer’s requirement. From synthesis and analysis using EM simulation and flow modeling to documentation and CAM programming using 3D modeling tools, the end result is a tightly integrated solution that has been designed to be manufacturable for high volumes as well as rapid first article production. |

|

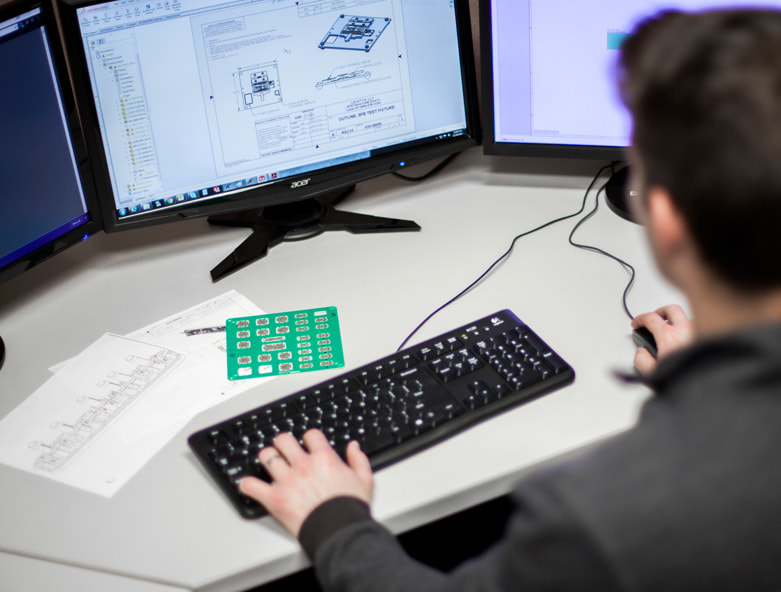

Assured Precision Machining

In order to support the high precision machining driven by high frequency microwave parts, Lexatys’ manufacturing employs Haas TM-1P CNC type equipment with automatic air gun, chip auger, programmable coolant nozzle, and rigid tapping that allows rapid prototyping and lights out machining to extend manufacturing capacity. CNC tooling programs are driven directly from 3D models developed in Dassault Systeme’s SolidWorks Professional suite of software. Integrated into the suite is AutoDesks’ HSM Works CAM tool that generates the toolpaths. With a low cost to change, engineers are encouraged to make design improvements early and often. |

|

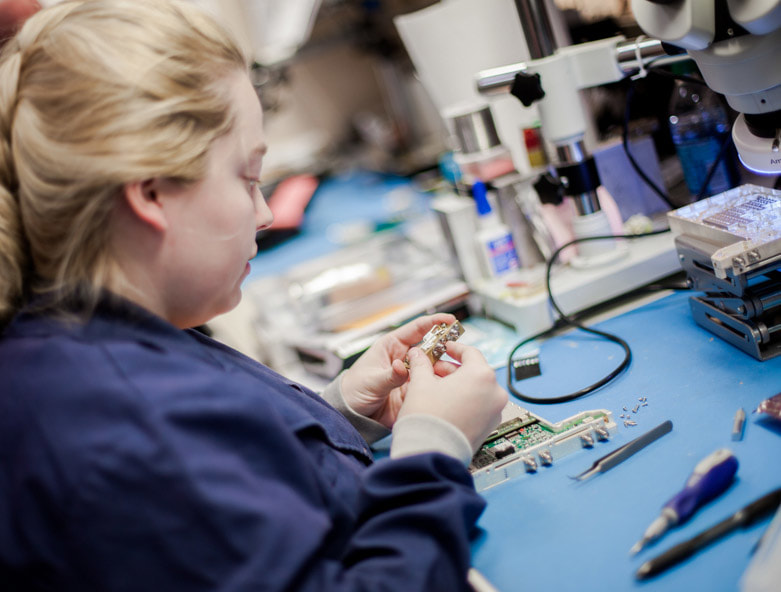

Certified Manual and Automatic Assembly Disciplines

Throughout the facility, fine hand tools and stereo microscopes are used extensively by our skilled operators. Each employee receives initial and recurrent training in the disciplines listed below. Lexatys has a full-time certified J-STD-001 soldering instructor to provide initial and recurrent training in this critical process.

|

Engineering Instruction

Experienced RF engineers routinely provide training and assistance to line personnel. Lexatys has developed an AS9100D and ISO9001:2015 compliant quality management system. Following the establishment of customer requirements and recording them in our CRM system, Lexatys engineers follow the procedures established in 767-73000 Design and Development to ensure compliance with expectations. During prototype, EDM production, and LRIP phases, all lessons learned, and beneficial improvements are recorded using processes called out in 767-71300 Documentation Change and Configuration Management. Lexatys personnel are committed to developing and recording core expertise in all areas of our discipline. The body of knowledge is accumulated into our controlled documents maintained in our PLM system based on Aras Innovator as well as our PDM system configured within Dassault Systeme’s PDM Pro distributed management tool.

Experienced RF engineers routinely provide training and assistance to line personnel. Lexatys has developed an AS9100D and ISO9001:2015 compliant quality management system. Following the establishment of customer requirements and recording them in our CRM system, Lexatys engineers follow the procedures established in 767-73000 Design and Development to ensure compliance with expectations. During prototype, EDM production, and LRIP phases, all lessons learned, and beneficial improvements are recorded using processes called out in 767-71300 Documentation Change and Configuration Management. Lexatys personnel are committed to developing and recording core expertise in all areas of our discipline. The body of knowledge is accumulated into our controlled documents maintained in our PLM system based on Aras Innovator as well as our PDM system configured within Dassault Systeme’s PDM Pro distributed management tool.

Contact UsIf you have any questions about Lexatys' services, capabilities, or manufacturing, please contact us today and we will be happy to assist you.

|

Capabilities Summary

| ||||||||

| lexatys-capabilitiesbrochure-web.pdf | |

| File Size: | 3480 kb |

| File Type: | |